Walking through the streets of San Gimignano and seeing all

the leather stores, I wondered if it was possible to get another leather

wallet. I soon realized I didn’t need

two different types or colors of wallets (no matter how nice the Italian

leather wallets are), and we continued on our unsuccessful quest to find fedoras. Leather materials always seem so appealing to

me. They seem to last forever and can

withstand almost everything. It’s bizarre

for me to think that all the leather I’ve seen originated from animal

skin. It just doesn’t seem possible that

the two could be related. After some

research, I started to realize how complex the process is to turn animal skin

into leather - so many intricate steps, all requiring the watchful eye of a

master of the trade. Even before the

leather can be tanned, all of the flesh, fat, and hair must be removed. Then the elaborate process of tanning can

begin.

|

| Tanneries |

Tanning is a process that permanently alters the protein

structure of the skin. It is also a

process which can provide the color for the final product. Before the tanning agents are added, the “pickling”

step increases the acidity of the hide to a pH ranging between 3.4 and 3.5, and

this range is very specific and crucial.

If the pH of the leather is too low, the leather will most likely be flat,

hard, and wet. It may also contain

grease spots on the surface. If the pH

of the final leather product is too high, the leather will probably be plump,

loose, and dry. It may also have a drawn

grain or be too soft.

After the conditions for tanning have been established, the

tanning agents can be added. Traditionally,

tanning used tannin (an acidic chemical compound) as the reagent. This is where tanning got its name. In modern times, scientists have discovered

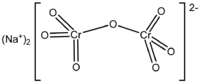

that chromium salts are the most effective for tanning animal skin. The most common tannin agent used in chrome

tanning (tanning in which chromium salts are used) is sodium dichromate. Chromium sulfate is then produced from the

sodium dichromate. Through a series of

reactions, the chromium sulfate produces polychromium(III) compounds. These polychromium compounds are subunits

that eventually link together the collagen in the animal skin. Before the linkage occurs, other reagents are

added producing ionized carboxyl groups in the collagen. At the low pH established by the “pickling”

step, the polychromium compounds can now cross-link with the collagen by

coordinating with the ionized carboxyl groups.

The pH is slowly increased to solidify this cross-link in order to keep

the leather sturdy and durable, yet slightly malleable.

|

| Sodium Dichromate |

Once these processes are complete, the leather is then worked

and sewn into the products we buy and enjoy every day. I love both my new belt and wallet and of

course the indescribable new leather smell that always accompanies them. It’s something I can’t get anywhere

else. I used to be ignorant of how

daunting of a task it is to turn animal skin into leather, but now I can

appreciate what I’ve bought even more!

It’s amazing the science that goes into such a drastic conversion, but

its engineered has allowed leather products to be available to more and more

people.

References:

http://thephilosophyofinteriordesign.blogspot.it/2011/03/trendy-decorating-with-leather-couches.html

No comments:

Post a Comment